-

Wider

areas of Central Balkan with particular mines of Timok's eruptive

basin and basin of Rudnik and Kopaonik, are some of the few richest

archeometalurgic provinces of Old Continent. Leaving the primary

farming period behind metallurgy and mining were implementing Balkan

development, development that testifies about the cultural

independence of both Balkan and Europe, in opposition to influences

spreading from Near East. Civilisation of Metal Age Europe started the

unrestainable progress on the heights by the Danube banks.

-

|

|

|

Eneolithic

mines shafts with access platforms on Rudna Glava mine |

- Early

Eneolithic mine

Rudna Glava near Majdanpek (5000 year B.C.) is an example of the oldest known technology of

copper acquiring. It was under researches in the period from 1968. to 1989. as a

part of the "Old Mining and Metallurgy of the Central Balkan" project, led by

Borislav

Jovanovic (Archeological Institute SANU) and

Ilija Jankovic (Museum of Mining and

Metallurgy in Bor). Only three decades after this discovery Rudna Glava was accepted as

one of the basis items of European civilisation.

|

|

|

Sacrificial altar

made for farmer's gods found in Rudna Glava shafts |

- Old Europe was colonized by population of eldest farmers which had

moved from the South of Balkan toward Central Europe, during the 7th and

6th

millennium of Old Era. Neolithic farmers worshipped Great Goddess - Great Mother, life

giver, ancient one. They celebrated life renewal of plants, in the

constant change of seasons.

- Usage of original metals-copper and gold opened portals of unknown

underworld, world so rich, but hidden that only Gods could show the way through it. New

Gods were bolt throwers, great blacksmiths or smelters. Deep in the

silent shadows of the

first mining shafts, natural ore canals, through which the ore was

flowing toward the

surface of Earth, for the first and the last time farmers Gods met

new, strong and

young Gods. They ruled over the powers unlimited, which forced matery to

miraculous metamorphosis from

shapeless ore blocks - new dazzling metal emerges.

- In the deepness of Earth Transformation of the

circle flow of

nature into the linear historical time occurred. At the same time parallel forms, of

natural and technological appeared. Consequences of this turnover can be understood

perhaps now a days.

|

|

|

Oldest

miner's tools, mallets - round pebbles with horizontal gutter |

- The

oldest mining technology known from Rudna Glava solved

many mysteries of the origin of primary mining and mineralogical knowledge indicating

hard and long way-way of new, inspiring technology. Developed skills of Rudna Glava miners

ore are indicated by the emptiness of the shafts no less than 20m deep.

- Long string of stone mallets, bigger river stones made from

volcanic rock, gives evidence of the higher specialization of primitive tools for

different and various productive purposes. As for the chopping of the

pieces different types of wedges were used, while the tools made from deer horns were used

for gathering the ore already chopped.

- When the ore vein was discovered,

the access platform was

built round its flooding canal. Afterwards the hard ore mass was broken into pieces by

circle hits of stone mallets, hanged either on a rope or leather belt. In the depths,

technique of sudden warming and cooling was used. Dishes from ceramic pantries of bigger

volume were used for pouring the water over the hot ore blocks. Cracked, blocks were

further smashed and broken into pieces.

- The ore obtained was taken to the

surface in bags, and it was

distributed further to the settlements near by. Further metallurgic

processes are

considered to be a part of technological circle of handworks in that

early period of metal

usage.

- Union with the experience of stone tools production is very

obvious in copying the most successful forms into new material - metal.

Creation of native

metallurgy and copper mining expires from the fact of relation between

the old and new

technologies, which in unbroken chain spring from each other.

- Knowledge acquired from Rudna Glava as much as from

Ai-Bunar

prehistoric mine placed in Bulgarian Trachia had altered completely developing and

hronologic chart of eldest metal industry in European pre-history. An opinion that

original knowledge on field of metallurgy was spreading from highly developed

centers of

Near East, over the Greek coasts and walleyes of Vardar and Morava toward Panonian plains and upper

flow of the river Danube was supported for the long period of time.

Apparently, mining areas

emerged from the areas of Central and East Balkans as the original focuses of independent

development of copper metallurgy.

- Arise of the new technologies determined the influence of the very

same legalities believed to be discoveries of modern time: increased demand for

raw

materials, gathering of mineralogical knowledge in the field of developed industry of

stone and flint tools, richness of visible and accessible ore, increased activities

of using

new metal tools, constant increase of metal demand, and finally production of

increased

quantities of metal in circulation (gold and copper). The last can be entitled

(If modern

aspects of production process allows) original metal market.

|

|

|

Pickaxe

- rake made

from deer horns, from the bottom of the shaft at Rudna Glava |

- Rudna Glava near Majdanpek is not the biggest mine of primitive

copper metallurgy but the archeometalurgic monument which shafts keep evidence of

the eldest technology of copper mining.

- The original mallets-rock made from deer horns long and massive

bone awls, or punches, pantries for ceramic dishes were found on the spot, stopped in the

course of time.

- When the

carbonate minerals of the copper (malachite and azurite) accessible to technology they had used

were exploited, Vinchan's miners of early

eneolith left the mine. By the long hand of coincidence nearby bearings of Majdanpek and

Bor became exclusive destinations of miners from Copper and Iron Age, which

automatically left Rudna Glava aside. This modest Iron and Copper ore

bearing (magnetite and halcopiryt) was used once more in Roman times - during the 3rd century A. D. That's why

the script of eldest mining remained in Rudna Glava legible and

understandable. As one of

the sort preserved in the changes of Eras, it made this place a spring of knowledge

about the genesis of the eldest copper metallurgy in pre-historic Europe.

Rudna Glava, eneolithic copper mine although damaged by works on

the surface excavation site of modern magnetite mine, have preserved all

information needed

for the complete reconstruction of eldest technology of acquiring carbonate and oxide ore

of copper. Essential value of the mosaic - gathered in one - is crystal survey of native

home crafts and experience. Some as vivid engravements of ancient

artists - Vincha's miners

emerged from past so distant it seemed lost, on this locality. They were inhabited in the

area from Northern Macedonia over the plains of Southern Panonia, during the period of 4th millennium B.

C. Tools and ceramic works made from local raw materials springed according to style

and form from distant traditions of Younger Stone Age (neolith), show no evidence of

foreign influence.

|

|

|

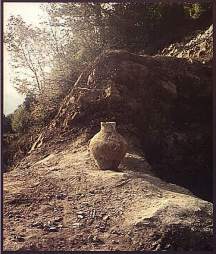

Amphora

from ceramic pantry on the excavation site |

- The ways of developing this eldest skill of ore smelting and metal

acquiring are dim and vague, lost in opaque mists of primeval dusks.

- Nevertheless

Rudna Glava has marked the beginning of primary mining and metalurgy representing it as common knowledge of Vincha's

populations inserted

in earning of every village. Ore was pulled out in times favourable spring or summer

months, it was cleared and prepared for proccessing and taken away toward villages. String

of technologic proccessing became developed in small manual smelteries and blacksmith

shops - from the forging of native copper to casting of the shorter strings of massive

copper tools and weapons. Quantities of the metal used for copper objects

designing were

preserved in many smelteries of Plochnik (smelter pantries). This village of Vincha's

culture in Toplica, testifies that tehnological improvement of the primary copper

metallurgy was exceptional.

- Improvements of copper casting acquired by constant

attempts to developed metal harder than copper (by adding arsenic, lead and

finally tin) brought to

creation of bronze alloy which exquisite qualities preserved its value till modern times,

at the end of 4th

millennium B.C.

|